If you’re in manufacturing or product design, you’ve probably wrestled with finding a reliable way to produce high-quality, complex metal parts without breaking the bank. Let me introduce you to Junying Die Casting Co.—they specialize in zinc die casting, and honestly, their work is next-level.

Why Zinc Die Casting?

Zinc die casting is a game-changer for creating durable, lightweight, and intricately detailed components. Think:

High precision (tolerances as tight as ±0.0015″!)

Cost-effective for large batches (no need for post-cast machining).

Superior surface finish—ready for plating, painting, or leaving raw.

Eco-friendly (zinc is 100% recyclable).

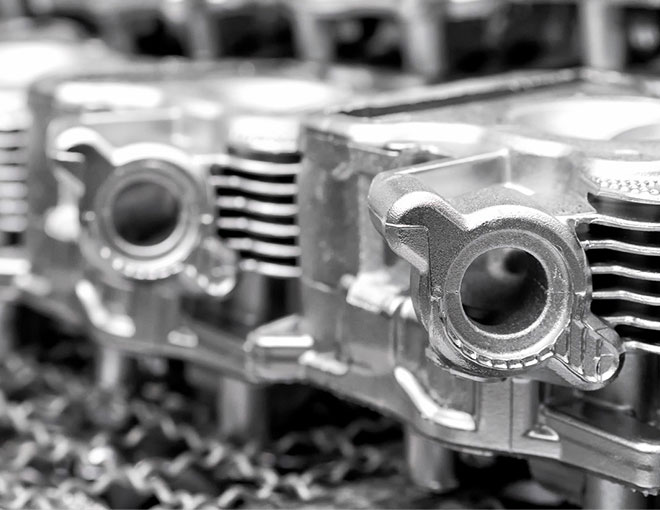

From automotive parts to consumer electronics, this method is everywhere. Check out this sleek die-cast lamp shade they produced—perfect example of how smooth and detailed zinc casting can be:

Die-Cast Lamp Shade

Caption: Zinc die casting delivers flawless finishes for even delicate designs like this lamp shade.

Bonus Tip: Dive Into Material Science!

If you’re nerding out over materials (like I do), don’t miss their recent article: What is Compacted Graphite Iron (CGI)?. It breaks down CGI’s properties, uses, and why it’s gaining traction in industries like automotive for engine components. Spoiler: It’s tougher than traditional cast iron but lighter!

Why Junying Die Casting Co.?

25+ Years of Expertise: They’ve nailed everything from prototyping to mass production.

Custom Solutions: Need a unique alloy or finish? They’ll tweak it.

Quality Assurance: Every part is rigorously tested (no surprises down the line).

Whether you’re designing a new product or optimizing an existing line, their team can help you cut costs and boost performance.

Ready to see what they can do for your project?

Visit https://www.diecasting-mould.com/zinc-die-casting